Made for you: Unmade on customisation and slashing retail return rates

Imagine a world where customers can visit you online or in-store, customise any product and then have it manufactured to their specification. Unmade is making that happen now. The company’s technology can plug in to any website or factory to give any retailer the ability to tailor their products to every customer, every time.

Those already signed up are seeing as many as 80% of customers plumping for the customisation option, while return rates are plummeting. Clearly Unmade is onto something.

CEO Hal Watts answers our questions on the technology, the intersection of tech and handicraft and the psychology of customisation that pushes return rates to less than 5%:

Could you explain the concept behind Unmade?

We provide the technology that enables brands to tailor all of their products for each of their customers. There are two sides to that. We build the technology that plugs into their website and provides an experience to the consumer. But then we also build the technology that plugs in to their factories so that every order can be manufactured in an automatic and scalable way.

We started because we were doing consultancy work for the UK Olympic team on aerodynamics of clothing for athletes. We came across this idea of custom fit because that’s what would really help with the aerodynamics, but we realised quite quickly that what you could do with it for a normal customer is actually more exciting really in terms of giving people what they really want in a product.

Customers are really excited and much more engaged with the products. It also massively reduces the amount of waste and cost to the brand because you don’t have a warehouse full of stuff that you don’t know if you’re going to sell. You’re only manufacturing on demand, so you’re effectively being paid before you manufacture something. From the perspective of the environment, in terms of waste, and also for the ecommerce brand it’s much better.

Do you work from the brand’s base product design and then identify the customisation options to adapt that?

The way we do it normally is that the brand sets certain parameters of the product. We work with them on the colours, the patterns, monogramming or the graphics that the customer can change and use. They set the parameters exactly where they want them, and then the customers can modify stuff within that.

Do you identify factories that can deliver this or can you plug in to a fashion brand’s existing manufacturer?

We can plug into any factory. We have factories that we’re already working with, but normally we work with a brand to identify the factories they already have in their supply chain that we think are the most ready for this, and then we integrate in those.

There are a lot of factories who are interested in doing this because they can get better payment terms than on traditional orders, so they’re willing to be flexible. We do have some factories where we ship through a distribution centre from the factory. It doesn’t have to be direct from factory to consumer. We recommend it because obviously you reduce the shipping costs and labour, and you can get the product to the customer faster. But there are actually quite a lot of factories that do direct shipping these days. Particularly in the UK they’ve been used to a very fast turnaround for topping up orders or run-ons for seasons, so they are often making product that has to get out very quickly.

We manufacture as soon as orders come in generally. We push the orders through as soon as we get them, so they manufacture pretty much every day.

How many shoppers choose the customisation option?

It massively depends on the brand because they have very different consumer demographics. Younger brands we see 75 to 80%, others are more like 30 or 50%. We’ve seen over 50% customisation on Farfetch for example. It really does depend on the consumer and it also depends how it’s messaged to the consumer.

On our site everything is customisable, people going to UMd expect to be customising their products. It’s probably why they’re there. Whereas if you put it in amongst your normal product lines you’ll get a lower customisation rate just because people aren’t necessarily looking for that.

What’s the scope for the level of customisation to grow?

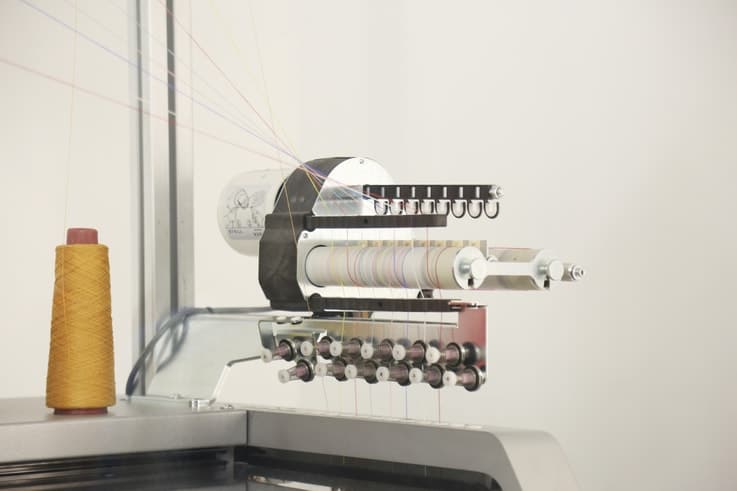

I think it’s ultimately limitless to be honest. Manufacturing of garments is becoming more and more automated, and therefore the level of customisation you can put in the process is increasing further and further. Right now, we only offer customisation from a colour and pattern perspective, but we’re already working on fit and embroidery and a lot of other embellishments that will be able to be used as well.

Is there a particular type of consumer that this appeals to?

I think younger consumers adopt it more readily because they are more savvy in terms of online experiences and shopping online. But we do offer the same experience in-store on iPad and you get much less of an age split there. So far we manufacture everything we do in Europe and that does mean there’s a certain premium just because the really low price points that people manufacture at you can’t necessarily achieve in European factories.

But I think as the technology scales and we get more efficient, then we’ll definitely grow and start offering to the lower segments of the market. I think to start with if you’re buying a luxury or premium product, you tend to spend a bit more time. You are willing to put the effort into customising it. It’s a slightly more considered purchase.

Does the customisation impact the lead time?

With Farfetch we put quite a long delivery time because we have to wait for it to go through all of their fraud checks and the payment stuff before we can manufacture their product. Then we allow them a week for shipping. I think we’ve probably shipped most of the products quite a bit faster than that, but on our side we do 10 days.

Customers are willing to wait a bit longer because it’s a more considered purchase. I’m sure if we shipped it faster it would probably increase the conversion even further.

What would help persuade a big retailer to try this kind of technology?

We’ve been doing quite a few customer trials with really big brands and the results have been really, really good. The brands that we’ve done this with after having trialled it with their customers have wanted to implement this on their sites as quickly as possible. That’s mainly because the level of engagement they see from consumers when they have this experience versus a normal shopping experience is massive.

One component is integrating it on their e-commerce platform, which works like an iFrame, so it’s a pretty standard thing to integrate. It’s just like when you have a YouTube video on your site, you can just copy paste the link in. Then we have a series of APIs to make sure that all the order management is handled correctly, and that it can be put in the cart because we don’t want to have an experience down the side. What we do is to make sure it can be added to cart with all of the normal items someone purchases. It goes through exactly the same checkout flow and everything of the e-commerce platform.

Then we generate all of the manufacturing data and we push that to the factory. We have a UI that the brand can log-in to and the factory can log-in to, and they can see what orders have come through and they’re on track. There isn’t much heavy lifting to be honest.

You have your own e-commece platform, do you have a physical presence as well?

No, we don’t. We had a couple of pop-ups when we started to showcase what is possible, but really we see our website as a showcase for large brands. Selling direct to the consumer is really not a focus for us, we have that website to show brands what is possible.

For some of the brands we’re talking to, physical retail is a big priority for them. Eighty percent of fashion is still sold in-store, so we definitely still see a huge importance in physical retail. We launch programmes with brands so they can offer that in-store, but it’s not something we’re going to do ourselves.

What’s your philosophy on how modern technology and the idea of traditional handmade craft can fit together?

What a lot of people don’t realise is that nearly all garments are made by hand, so every T-shirt you’ve ever bought has been assembled by someone somewhere. I think there is this kind of romanticising of the craft. Obviously luxury fashion is going to be quite different, but all of the other stuff is handmade as well. It’s just no-one wants to tell the story of where and how it is handmade.

I think technology sits quite well alongside craft. Since the industrial revelation it’s always been a question of how does technology affect manual craft. I read somewhere that there’s 50 million people employed in garment assembly globally and most of those people are not in the luxury sector. They will be manufacturing for the large consumer brands. Ultimately the trend that’s going on everywhere is that automation is going to eliminate a lot of those jobs probably over the next decade or so.

The other thing is that the garments we manufacture with Opening Ceremony are made at Johnstons of Elgin in Scotland, which is one of the most premium factories in the world. They manufacture for a lot of the luxury brands and they are very old factories. The level of craftsmanship there is absolutely amazing. I don’t think technology necessarily eliminates craftsmanship. In some ways, it can be used to enhance it as well.

How do you think Unmade benefits designers’ longer-term relationships with their customers?

I think it creates a much deeper level of conversation. If you’ve been involved in the creation of your product, it’s very different than buying what was on offer. The return rates we’ve seen on custom products have been under 5%. The typical return rates in fashion are 30 to 40% for online purchases. I think it really does create a different level of involvement from the customer and the product.

Is the psychology of people being invested in that product because they’ve made it that make the difference?

I think it is because of that. I think it’s because it arrives and you already feels like it’s yours because you spent time creating it. You know it’s been made for you, so it feels quite different from buying a mass-produced product, which you know there are 20,000 of out in the world and you can send it back because there’s another 19,999 kicking about. Whereas I think if you’ve been actually involved in the creation of it and you know it’s been made specifically for you, you feel a completely different affinity to the product. I mean we accept returns on anything, for any reason, and we still see a much, much lower return rates.

Do you think that links into the customer’s ability to tell a story about that product as well?

I think so. For me what differentiates a premium product from non-premium is usually there is a story behind it. If you’re buying a classic Burberry trench coat, they’re telling the story behind the product and why it exists and what heritage of that product is. Whereas if you go to another large brand, they don’t necessarily tell the story of the product because there isn’t necessarily a story to tell there.

I think what customisation allows is to create a story around the product. Even if it’s not got the heritage of a very old brand, you’re creating a story between the person and the object because they can say to their friends, “I customised it.”

Are there any brands or companies that you think are doing interesting things?

As a business the kind of companies or brands that we relate to are the ones that are doing things more sustainably. I think it’s really the most important issue. Fashion is the second most fleeting industry in the world. Lots and lots of sustainability needs to happen in the industry or needs to be improved. Anytime we see a brand that’s doing something exciting in that space that’s someone we look towards. I think Adidas has done some really cool stuff with the fully recycled shoes recently where they were getting plastic out of the ocean and re-spinning that and using it to manufacture the shoes from scratch.

What is next for Unmade?

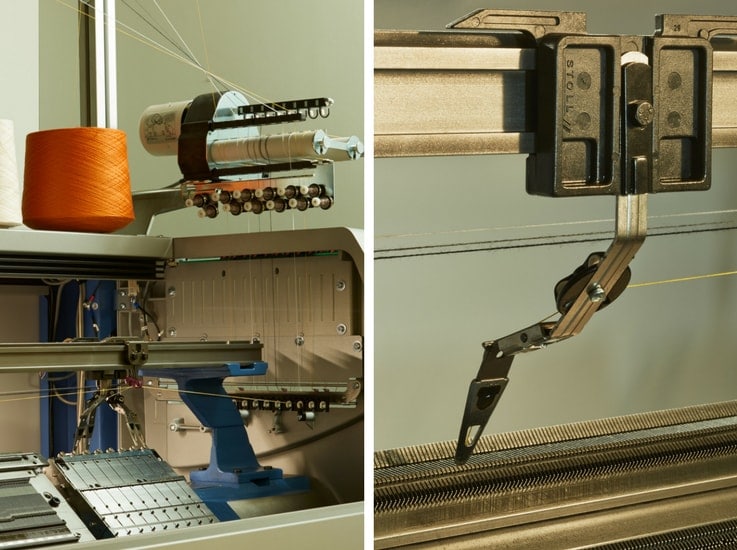

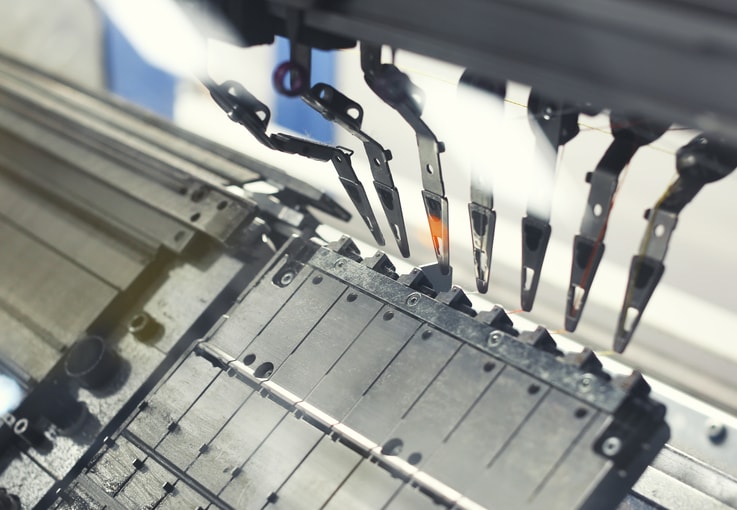

The big thing for us is that so far all of the products we put out have been focused around knitwear. That because that’s the manufacturing process that we worked on first. A huge part of what we’re doing is expanding to all other product categories, so we’re going to start offering embroidery and digital printing and then expanding into footwear and a lot of other different product categories. It’s really taking the concept we’ve already developed and proven and taking it to other product lines.

Find out how storytelling can improve your retail business. If you want more content like this, or to keep up with the latest retail trends, click hereto join our community.

Images courtesy of Unmade